Exchange rate

The natural rubber wastewater treatment system is a detailed calculation procedure of the implementing unit of this system to help the natural rubber wastewater discharge into the receiving environment will be in line with the regulations. The government's requirement is to help protect the environment at the place of production.

Characteristic wastewater of natural rubber production

The natural rubber industry has made economic development and contribution to the economy of the country but, along with the rapid economic development, environmental problems caused by this industry. It is also a worrying issue that waste water produced when not treated thoroughly will increase the risk of pollution. So, businesses need to seriously implement waste water treatment system in this natural rubber industry

Based on the manufacturing steps of the production company, waste water containing latex, NH3 high, BOD, COD, SS high; The pH is low (the process of adding acid to the pus). This is the basis for implementing this system.

Waste water treatment technology in natural rubber production

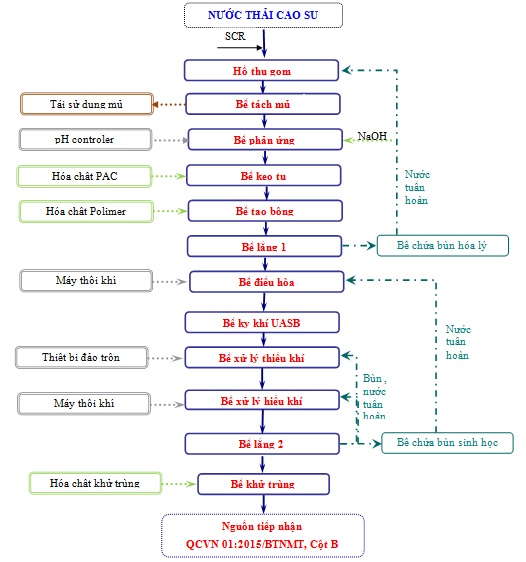

Wastewater treatment in the natural rubber industry is carried out with the following technologies:

Wastewater generated from the production area is collected and transported to the wastewater collection pit before being disposed of in the waste water collection pit. .

Wastewater from the receiving pit leads to the pumeral tank remaining in the wastewater collected and recycled into the process of producing the water to be fed to the reactor to stabilize the pH in the effluent. .

Reactor: The pH adjuster is immersed in the reactor, aiming to stabilize the pH in the effluent and be controlled by the PH controler. After stabilizing the pH of the effluent is directed to the cotton-clotting tank.

Cotton-clotting tanks are added with chemicals to precipitate the suspended solids in the wastewater, forming large deposits with high settling capacity.

Sedimentation tank: After forming large mud flotas, wastewater is taken to the sedimentation pond for sedimentation, the sediment is deposited into the regulating tank.

The regulating tank is responsible for stabilizing the wastewater flow for the rear treatment facilities.

Anaerobic ponds: Waste water from rubber production has high concentration of pollutants, BOD, COD, N, so wastewater is taken from anaerobic digestion tank to anaerobic biological treatment tank to avoid load shock for treatment facilities. Biology behind. The anaerobic digestion tank is responsible for the dissolution of organic matter in wastewater, reducing the concentration of BOD, COD, and facilitating the efficient biological treatment of the latter.

Exhaust gas tank: Waste water after reduction of COD, BOD from anaerobic bio-tank, waste water is led to the tank lack of sign. The purpose of the aerobic biogas plant is to receive wastewater from the anaerobic tank, enabling the aerobic microorganisms to adapt to wastewater, facilitating bioremediation Processed gas is effective. In anaerobic pools, the microbial strains of dehumidifiers act to degrade pollutants, reducing BOD, COD, N, P.

Aerobic Pool: Wastewater after aerobic biogas is led to aerobic biogas plants for more thorough treatment than BOD, COD, N, P. Under the action of aerobic microorganisms, pollutants in waste water are decomposed to CO2, H2O and other non-contaminating compounds.

Sedimentation tank: The wastewater after treatment will overflow into the sedimentation tank. The mixed waste water and activated sludge in the settling tank are separated by the effect of gravity. Activated sludge is bonded to each other, forming a large muddy slurry settling down to the bottom of the settling tank, the clear water being collected in the trough and taken to the disinfection tank. Excess sediment in the settling tank is pumped out into the silt reservoir or circulated to the microbial tank as needed.

Disinfection tank: The disinfectant is placed in a disinfection tank to kill the bacteria in the waste water before it is allowed to be discharged into the environment. Waste water after treatment is allowed to discharge to the receiving source, reaching QCVN 01: 2015 / BTNMT, column B.

AN DINH TECHNOLOGY TRADING & SERVICE CO., LTD

Office: 73, 3st., Hamlet 5, Binh Hung Ward, Binh Chanh Dist., HCMC, Vietnam

Tel: 089 810 1800

Website: www.andinhtech.com / www.autodoorvn.com

Hotline