Exchange rate

Waste water treatment in the brewing industry is one of the systems that have been applied and have been built and expanded more and more in recent years. With this system, it will ensure that brewing units are not worried about the problem of wastewater when it is produced in a regulatory environment.

Typical brewing waste water

The brewing industry's current effluence is on the rise, as people's needs are rising, as has previously led to a growing number of beer companies. It is because of the wide open so there should be a sewage treatment system in the brewing industry to be able to ensure the production of your business properly as well as to ensure the water supply after production to the lips. The school admits the government regulations promulgated unpolluted.

Wastewater from the beverage industry in general, and the brewing industry in particular, have high levels of waste water, high TSS, COD, BOD, nitrogen, high phosphorus ....... In nutrient-rich wastewater, the amount of bacteria in the waste water is high. If wastewater treatment is not effective in the brewing industry, discharge into the environment will cause serious damage to aquatic organisms and other environmental components (such as water environment, soil environment, environment, etc.). gas).

Brewery waste water treatment technology

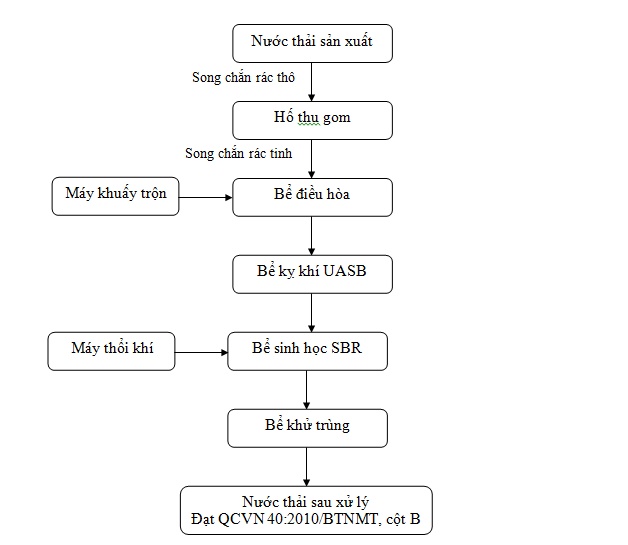

Waste water treatment technology brewing industry as follows:

- Collecting pit:

+ Wastewater generated from the production area is collected by the collection route arranged in the factory and delivered to the collection pit for concentrated wastewater before being pumped to the wastewater treatment plant. At the collection pit there is a rough grille layout, the purpose of using the solid waste to remove solids, large scale residues in the waste water such as beer, beer, marmalade ....

+ Water from the collecting pit is pumped to the air tank. Due to the large amount of suspended solids in the wastewater, the wastewater is passed through the refuse collection bin (or refuse collection device) to remove the majority of suspended solids in water. Discharge out. Waste is collected and processed. Wastewater after removal of suspended solids is introduced into the conditioning tank.

- Air tanks:

The regulating tank is responsible for regulating the flow and stabilizing the concentration before bringing wastewater to the rear unit. Avoid fluctuations in organic matter content in wastewater that affect microbial activity during biological treatment. Facilitate the rear structure to stabilize and achieve high processing efficiency.

+ In order to avoid sedimentation in the air-conditioning tank, the mixer is installed in the tank to disrupt the wastewater in the tank and at the same time stabilize the concentration of pollutants in the waste water before being pumped to the tank. Next treatment works.

From wastewater treatment tank is pumped with stable flow into anaerobic biological tank.

- Anaerobic biological tank

Waste water after conditioning, stabilizing the flow will be pumped into anaerobic tank. Here, due to the decomposition of organic matter in the anaerobic environment, the anaerobic organisms grow, develop and metabolize pollutants in waste water into cellular nutrients, reducing Pollution concentration in waste water. After anaerobic treatment, the wastewater is fed to the back treatment.

- Biosolids (SBR)

+ Waste water after treatment in the anaerobic biological tank has been reduced BOD, COD, but not yet reached the permitted discharge standard, so it must be further processed by subsequent treatment stages.

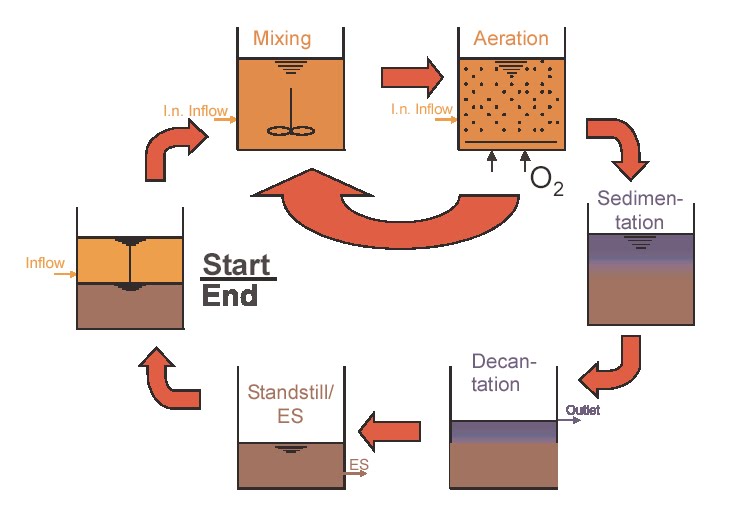

Sequencing Batch Reactor (SBR), a biological wastewater treatment tank, is a continuous biological waste water treatment tank.

+ The operating cycle of the tank with 5 phases is as follows:

Wastewater after biological treatment and sedimentation in SBR tanks, the water in the upper SBR tank is attracted to water by surface water collection system. The sludge in the tank (microbial fraction) will continue to be used in the treatment. In the case of excess sludge, excess sludge will be disposed of.

- Disinfection tank

The water in the SBR treatment was collected and taken to the disinfection tank. At disinfection tanks, disinfectants (chlorine or ozone) are used to disinfect coliform wastewater before discharging into the receiving source. Waste water after treatment meets the emission standards of QCVN 40: 2010 / BTNMT, Column B.

Advantages of Brewery Waste Water Treatment Technology

When implementing the technology of wastewater treatment brewing industry has the following advantages:

+ High efficiency of wastewater treatment

+ Low operating costs

+ Easy to manage and operate the treatment system.

Along with some other great details

AN DINH TECHNOLOGY TRADING & SERVICE CO., LTD

Office: 73, 3st., Hamlet 5, Binh Hung Ward, Binh Chanh Dist., HCMC, Vietnam

Tel: 089 810 1800

Website: www.andinhtech.com / www.autodoorvn.com

Hotline