Exchange rate

Pesticide waste is one of the sources of toxic waste. At the companies producing pesticides, the amount of wastewater is not much but the toxicity is very high. Therefore, if the waste water treatment pesticides are not up to standard but released into the environment will greatly affect the environment.

I. Characteristics of wastewater in the chemical pesticide industry

Wastewater produced by the chemical pesticide industry is not much, mainly from the process of cleaning chemical equipment after the working time of the day. The pollutants are extremely dangerous to the ecosystem if not effectively treated before discharge.

Regarding the composition of pollutants in wastewater: mainly organic chemicals, chemicals of the halogen group, benzene, chemicals with structures of circuits hardly biodegradable and chemistry C. And volatile substances.

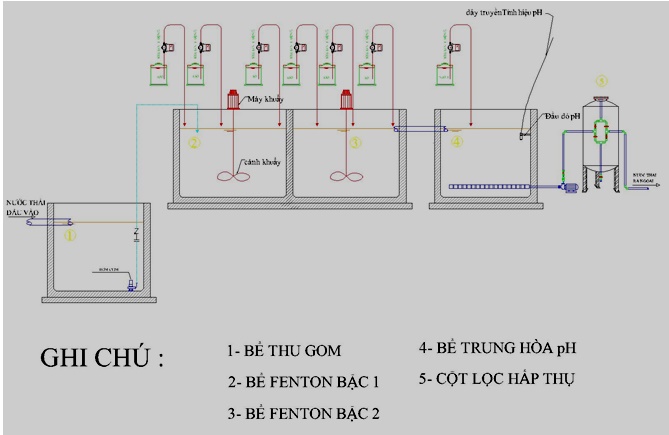

II. Waste water treatment technology in chemical pesticide industry

III. Explanation of wastewater treatment technology in chemical pesticide industry

Waste water production: the amount of wastewater generated is not high, mainly from the process of cleaning the tools collected in the collection tank, the waste water collection tank and the sewage pump to the treatment facilities.

Wastewater from the pit is pumped into Fenton Level 1 and 2 treatment tanks to treat COD and cut off circulating wastewater. Due to the nature of the wastewater is the chemical composition of circulating carbon circuits biodegradable biodegradation and conventional chemistry, the application of the process by means of strong oxidation to break off the C ring circuit of Compounds, forming new substances do not pollute the environment anymore.

The chemicals used in the Fenton process are H2SO4 and FeSO4; in addition, for high Fenton process efficiency, the reaction takes place in an environment where the catalyst H2O2 is added.

Wastewater after Fenton Level 1 treatment, effluent treatment COD, and effluents in wastewater accounts for about 50-60%, but is not allowed to discharge. Therefore, for more efficient treatment, the effluent is fed to the 2nd level Fenton treatment. The wastewater is treated with second level Fenton tanks, the COD norm is allowed to be discharged into the environment. Want to be allowed to discharge into the environment must continue to be treated on the pH and control the concentration of ions in waste water.

To adjust the pH of the effluent after the Fenton process, the effluent is led into the pH neutral tank. Here, the pH-adjusted chemical is injected into the pump and controlled by a pH controller.

After adjusting the pH, wastewater is injected through the ion exchange column before discharge into the environment.

Waste water after treatment meets discharge standards according to QCVN 40: 2010 / BTNMT, column B

AN DINH TECHNOLOGY TRADING & SERVICE CO., LTD

Office: 73, 3st., Hamlet 5, Binh Hung Ward, Binh Chanh Dist., HCMC, Vietnam

Tel: 089 810 1800

Website: www.andinhtech.com / www.autodoorvn.com

Hotline